Project Showcase

Types of Project

Types of Work

Regions

Results for "Type of Project > Offsite & Utilities"

Changi Airport Fuel Hydrant Installation (CAFHI)

Changi Airport Terminal 4, Singapore

ENOC – Refinery Expansion – Tankage Facilities Project

JAFZA Dubai, UAE

GMR Energy 2 x 400 MW CCP Project

Jurong Island , Singapore

Improved Water Quality Supply at Dhahran

Dhahran, Saudi Arabia

Map Ta Phut MOC Cracker Plant II (Tank Farm Unit)

Rayong, Thailand

SABIC (SHARQ) – SHARQ 3rd Expansion

Jubail, Saudi Arabia

SATORP (Package 6 – Refinery Tank Farm)

Jubail, Saudi Arabia

Saudi Kayan Petrochemical Complex

Jubail, Saudi Arabia

SEG – ISF Project (Jubail Interface Supply Facilty)

Jubail, Saudi Arabia

Changi Airport Fuel Hydrant Installation (CAFHI)

- PROJECT DESCRIPTION

Civil & mechanical works:

- 2 kilometer pipeline with capping beam

- 33 fuel hydrants

- 5,200 DB for shop & field piping installation

- Construction of 4 main valve chambers

- Underground piping works include sheet piling, reinforced concrete piling, excavation, backfilling, concrete & steel bar reinforcement

- Pipe-jacking for the tie-in area

- Pre-commissioning works

SCOPE OF WORK:

Construction & Pre-commisioning:

- Civil

- Piping

CLIENT: Changi Airport Fuel Hydrant Installation Pte Ltd

LOCATION: Changi Airport Terminal 4, Singapore

OWNER: Changi Airport Fuel Hydrant Installation Pte Ltd

DURATION: Jan 2015 - Feb 2017

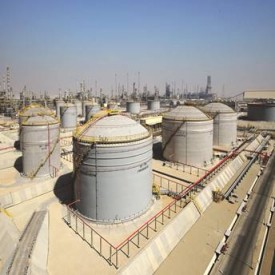

ENOC – Refinery Expansion – Tankage Facilities Project

- PROJECT DESCRIPTION

EPC of 12 tanks, with 450,000 cbm storage capacity. Scope includes associated civil works, piping connections (including tie-in to existing refinery), mechanical works, electrical and instrumentation works and fire-fighting facilities

SCOPE OF WORK:

Engineering Design, Procurement and Construction:

- Civil

- Tankage

- Piping & Structures

- Equipment Installation

- Electrical & Instrumentation

CLIENT: ENOC Processing Company (LLC) (EPCL)

LOCATION: JAFZA Dubai, UAE

OWNER: ENOC Processing Company (LLC) (EPCL)

DURATION: Mar 2017 - Jan 2019

GMR Energy 2 x 400 MW CCP Project

- PROJECT DESCRIPTION

- BOP Mechanical & Piping Works (PACKAGE 2)

- EPC 7 tanks for Fuel Oil, NeWater, Fire Water and Demin. Water (105,250 cbm); Tank construction works mainly include general fitting, welding works, Pipes and fittings erection.

- Shop fabrication and site erection of BOP piping (SS & CS) of around 55,000 DB.

- Site erection of heavy equipments of around 1,100 tons.

- Testing and pre-commissioning of the system to ensure plant readiness for energisation, and provide skilled manpower support to Samsung C&T (Main Contractor) for the commissioning works

SCOPE OF WORK:

Engineering Design, Procurement and Construction:

- Tankage

- Mechanical & Piping

CLIENT: Samsung C&T

LOCATION: Jurong Island , Singapore

OWNER: Samsung GMR

DURATION: Sep 2011 - Jul 2013

Improved Water Quality Supply at Dhahran

- PROJECT DESCRIPTION

1 no. of new drinking water tank

SCOPE OF WORK:

Engineering Design, Procurement & Construction:

- Tankage

CLIENT: Saudi Aramco

LOCATION: Dhahran, Saudi Arabia

OWNER: Saudi Aramco

DURATION: Mar 2015 - Apr 2016

Map Ta Phut MOC Cracker Plant II (Tank Farm Unit)

- PROJECT DESCRIPTION

- Basic & detailed engineering for 9 nos. of Spherical and 11 nos. of Atmospheric Tanks

- Spherical Tanks under ASME Sect VIII Div II; Atmospheric Tanks under API 650/651 code

- Spherical Tanks products: HP Ethylene/Propylene & C4

- Atmospheric Tanks products: Cracker bottom, mixed Xylene, Naphtha, Benzene, Toluene, Pyrolysis Gasoline

- Capacity of TFU – 190,000 cum; Tanks (empty weight) – 9,600 Tons; Piping – 150,000 DB

Safety man-hours w/o LTI – 4,800,000 mhrs - Design & supply of materials, fabrication and erection of tanks, testing, inspection & pre-commissioning

- Design for spherical tank based on ASME Div II which results in material cost saving for client, via use of thinner tank plate materials

SCOPE OF WORK:

Engineering Design, Procurement & Construction

- Civil

- Tankage

- Piping & Structures

- Equipment Installation

- Electrical & Instrumentation

CLIENT: Map Ta Phut Olefins Co. Ltd. (Siam Cement Group)

LOCATION: Rayong, Thailand

OWNER: Map Ta Phut Olefins Co. Ltd. (Siam Cement Group)

DURATION: Jan 2007 - Apr 2009

SABIC (SHARQ) – SHARQ 3rd Expansion

- PROJECT DESCRIPTION

- EPC works for 9 nos. of tanks, of which five are site-erected tanks & four are shop-fabricated tanks

- All are cone roof tanks T-8640 (20 meter diameter by 20 meter height)

- BTX storage tank with internal aluminum floater

- Tanks were designed according to API 650 & roof were designed according to API 620 due to climate conditions

- Job scopes include all works related to tanks, such as level indicators, instruments & foam chambers

SCOPE OF WORK:

Engineering Design, Procurement & Construction:

- Tankage

- Piping & Structures

CLIENT: Shaw Stone & Webster Arabia (Project Management Control)

LOCATION: Jubail, Saudi Arabia

OWNER: SABIC (SHARQ)

DURATION: Sep 2007 - Sep 2009

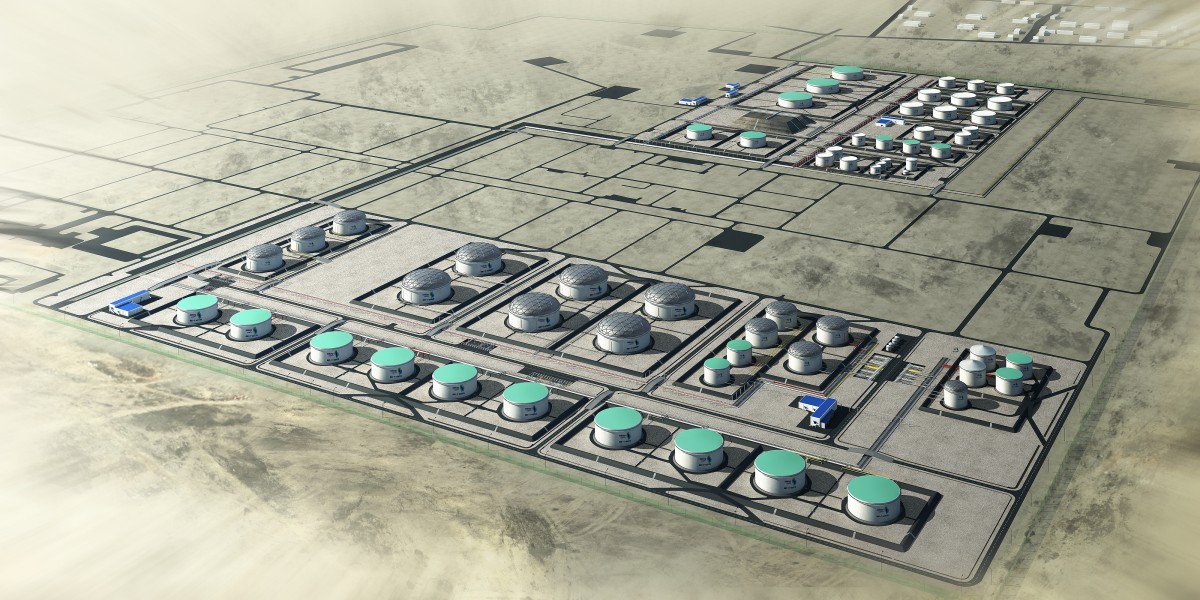

SATORP (Package 6 – Refinery Tank Farm)

- PROJECT DESCRIPTION

- Total storage capacity of 1.7 millions cbm

- Total of 62 ATM tanks and 8 bullet tanks

- Holds record for largest bullet tank in the world to have been assembled in the history of oil refinery, weighing 1,293 metric tons, 84 m long and an external diameter of 9 m

- Products stored include regular gasoline, RBOB gasoline, jet A1, diesel, benzene, paraxylene, propylene, C3 and / or C4, fuel oil, black material and naphtha

- Mechanical works include installation of 100 GC pumps, 4 positive displacement pumps, 88 mixers, 24 small tanks and vessels, 5 package units, 23 transformers, HVAC equipment

- Eelectrical & instrumentation works include new substations and lighting facilities, 3 instrument control rooms, FCR, PIB and PCR cabinets, cable routine, tank gauging systems, fire & gas detectors

- Commissioning supports

SCOPE OF WORK:

Engineering Design, Procurement & Construction:

- Civil

- Tankage

- Piping & Structures

- Equipment Installation

- Electrical & Instrumentation

CLIENT: Saudi Aramco Total Refining & Petrochemical Company

LOCATION: Jubail, Saudi Arabia

OWNER: Saudi Aramco Total Refining & Petrochemical Company

DURATION: Jul 2009 - Dec 2013

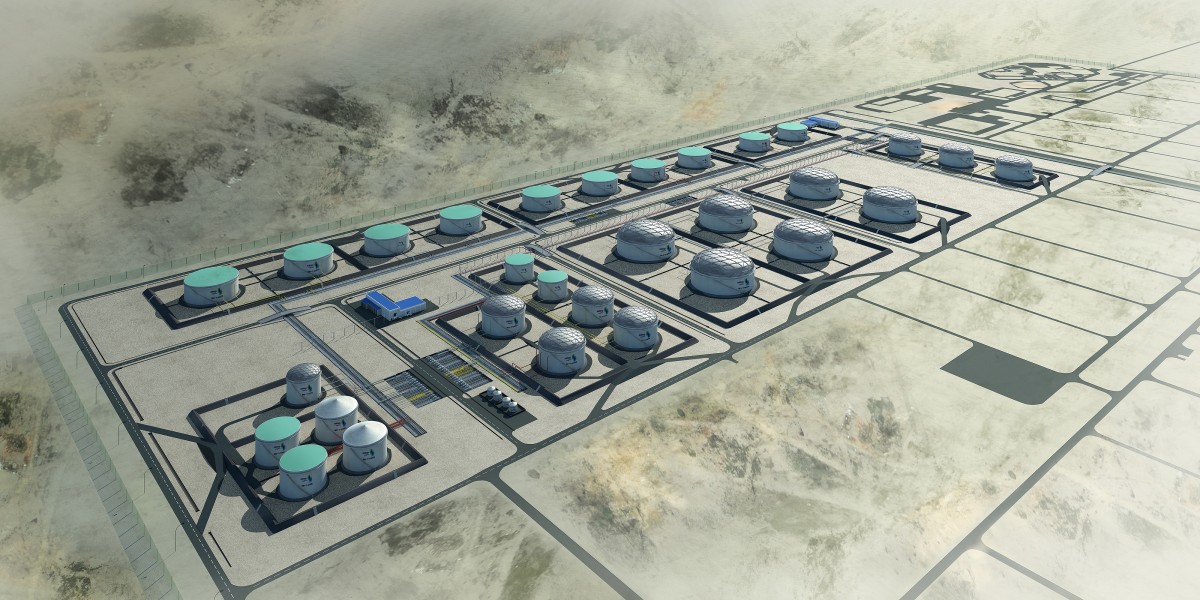

Saudi Kayan Petrochemical Complex

- PROJECT DESCRIPTION

- Located in the Saudi Kayan Petrochemical complex in Al Jubail, Saudi Arabia

- EPC for Mechanical construction, piping and civil works for storage tank farm located at a greenfield site

- 24 numbers of atmospheric storage tanks with a total capacity of 67,000 cbm of carbon steel and stainless steel

- Detailed engineering for the tanks, tank foundations, tank bund walls, pipe supports and electrical engineering works. The facilities were designed to American standards

- The products stored includes Caustic, Acetone, Raw Hexane, MEG, DEG, TEG, Benzene, DMF, Methanol, Glycol, Ethanolamine, etc

- Seismic design was considered for the design of the facilities

SCOPE OF WORK:

Engineering Design, Procurement & Construction:

- Civil

- Tankage

- Piping & Structures

- Equipment Installation

- Electrical & Instrumentation

CLIENT: Fluor Daniel

LOCATION: Jubail, Saudi Arabia

OWNER: SABIC (Saudi Kayan)

DURATION: Jan 2008 - Jan 2010

SEG – ISF Project (Jubail Interface Supply Facilty)

- PROJECT DESCRIPTION

- 2 nos. of MTBE tanks (16 meter diameter x 18.5 meter height). External dome roof with internal floating roof

- 2 nos. of P95 tanks (32.1 meter diameter x 19 meter height). External dome roof with internal floating roof

SCOPE OF WORK:

Engineering Design, Procurement & Construction:

- Civil

- Tankage

- Piping & Structures

- Equipment Installation

- Electrical & Instrumentation

CLIENT: SEG - Sinopec Engineering Group

LOCATION: Jubail, Saudi Arabia

OWNER: SATORP

DURATION: May 2015 - Mar 2017