Saudi Arabia

Rotary Arabia, a subsidiary of Rotary Group of Companies, is one of the premier EPC contractors in the Kingdom of Saudi Arabia, specializing in tank farms and tankage construction works. We are able to fulfill the most demanding requirements of engineering, procurement, construction and project management works - from small scale contracts to large EPC Turnkey projects.

Founded in 2007 in the Industrial City of Jubail, we have made firm footprints with our quality and efficient works. We have built a reputation known to many major clients within the kingdom, and at the same time forged good relationships with a wide array of partners in the oil & gas, petrochemical, petroleum and construction industries.

Being committed to Health, Safety, Quality & Productivity, we renewed our ISO 9001 certification in May 2016. This demonstrates our dedication toward continuous improvement and superior performance in all aspects of our business.

We pride ourselves as a partner with in-depth expertise as an EPC turnkey solution provider in the fields of bulk liquid storage terminals, tank farms, offsite & utilities for refineries and petrochemical plants. In addition, we are capable in the expansion & upgrading of existing terminals, and providing maintenance for process plants.

We firmly believe no job is too big for us - in fact, we had supplied and installed the largest bullet tanks in the world! Be it atmospheric carbon steel tanks or the most complicated and largest of bulk storages, we are able to undertake such EPC projects that fulfill your operational requirements. Using the latest technology, we possess the expertise to build tanks ground-up to achieve high productivity and efficiency. We are also experienced in the construction of double-walled tanks, cryogenic tanks, horizontal vessels etc.

Rotary has a total of 5 fabrication workshops spanning across key regions in the Middle East and Southeast Asia, strategically align with our group’s direction for the support of our multinational projects with our unique execution plans. Apart from providing fabrication support to our EPCM services in these regions, our workshops are fully equipped with capabilities to support fabrication projects as required by our clients worldwide.

Occupying a combined total area of more than 30 hectares, these 5 workshops are capable of fabricating more than 1.2 million DB of piping, 8,000 tonnes of structural steel, and 45,000 tonnes of plates rolling per year. With our effort in expanding our presence in the Middle East, we are expecting our 6th workshop to be completed in Fujairah, UAE by Q3 2017.

Click here to view Our Fabrication Services

In Jubail, Rotary has 12,000 square meters of sheltered fabrication shop with office facilities on our 8-hectare site. Our fabrication shop is divided into bays for piping, tankage, structural & bench work area. Each bay area is complete with facilities like cutting and welding machines, overhead cranes among other equipment. The site also has facilities for painting and curing, and pre-assembly areas for tanks and other materials delivered.

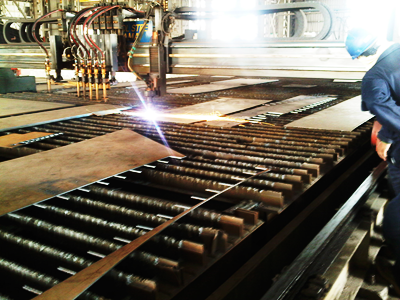

Our workshop is equipped with a CNC plasma cutting machine capable of cutting steel plates of 45mm in thickness, and an in-house hydraulic plate roller (2000 Tons) capable of fabricating steel plates up to 3 meters wide and 45mm thick. In addition, we also have ready-to-use automated pipe welding machines, and varying kinds of welding machines and generator sets operated by our highly-skilled and experienced team.

In the spirit of keeping abreast with modern construction methodologies, we seek to continually improve methods and procedures in our SOP so as to meet the requirements of all our clients.

From the start of each fabrication stage, we are committed to maximizing productivity. We utilize efficient cutting machines – CNC and Auto cutting/bevelling machines, and hydraulic rollers for all structural steel materials.

At our blasting and painting facilities, we employ auto blasting within the chamber in addition to manual blasting and painting works to improve efficiency.

In addition, our approach in conventional tankage construction is aided with advanced automated welding processes. This is supported by our highly-skilled welders who make use of these methods to produce works of the highest quality.

More recently, we have switched to jack-up method for large tankage erection works. This keeps us competitive in the construction of projects which are bigger in size.

Our commitment to quality is spearheaded by our highly-experienced QC team, who is readily-available for site or shop mobilization. With the aid of a well-trained team, our clients can be assured of the quality of our outputs.